Request a Quote

Why “Dust First, Wash Second” Saves Water, Reduces Detergent, and Delivers Cleaner

In the Middle East, Central Asia, and many parts of Africa, the biggest enemy of carpet cleaning isn’t just stains—it’s dust, sand, and fine grit. Many carpet washing plants learn this the hard way:

If you wash a dusty carpet first, dry dust turns into wet mud.

Then you spend more water, more detergent, and more time trying to rinse it out.

That’s why professional facilities follow one proven workflow:

Dust First → Wash Second → Spin Dry → Faster Drying & Delivery

The common question: “Can we just wash it directly?”

You can wash without dusting—but in dusty regions it often causes:

• Higher water consumption (more rinsing to remove muddy residue)

• Higher chemical use (more detergent needed to fight embedded dirt)

• Longer cycle time (lower daily capacity in your carpet washing line)

• More rewash & complaints (especially for mosque carpet cleaning)

• Heavier wastewater load (more sludge, more filter and drainage stress)

In short: if your carpets are loaded with dust and sand, pre-dusting is not optional for consistent quality.

What “Dust First” removes

Carpets hold dirt in layers:

When you wash first, water pushes fine particles deeper, creating sticky mud that clings to fibers.

When you dust first, you remove dry particles before they become mud.

Result: brighter appearance, cleaner rinse, fewer residues, and a more professional finish.

How “Dust First, Wash Second” saves water and detergent

Think of dusting and washing as two different jobs:

If you remove dust first, washing becomes easier:

✅ Less detergent required (chemicals don’t get “wasted” fighting dust)

✅ Fewer rinse cycles (mud and foam clear faster)

✅ Cleaner wastewater (less sludge load)

✅ More consistent results across mixed rug types

Why this matters for your business: quality + speed = profit

For carpet washing factories and commercial cleaning operations, pre-dusting improves the metrics that directly impact ROI:

This is exactly why more investors searching for carpet cleaning business equipment choose a carpet dust remover machine as part of the line.

Recommended 4.2m workflow for professional plants

A high-efficiency carpet washing line typically follows:

Step 1 — Dusting + Washing Integration (APEX-4200)

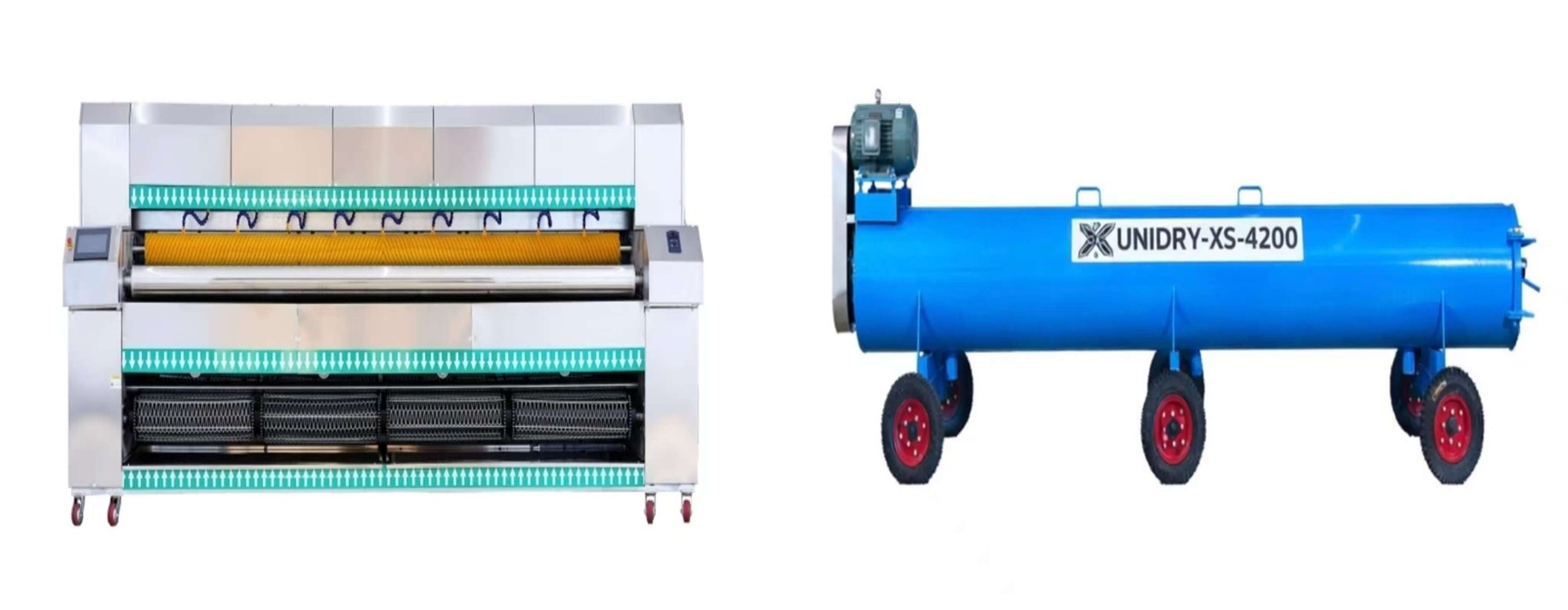

APEX-4200 (4.2m, 8-disc) is an automatic carpet washing machine with dusting + washing integrated—built for industrial operations.

Key advantage for diverse markets:

This flexibility supports better quality control with fewer damage risks.

Step 2 — Fast Water Extraction (UNIDRYER-4200)

After washing, UNIDRYER-4200 (4.2m) works as a carpet spin dryer / rug spin dryer, removing water quickly through centrifugal spinning.

Benefits:

When you should definitely invest in a dusting function

A dusting stage becomes essential if:

If you are operating professionally, the real question isn’t “Should we dust first?”

It’s: “How much money are we losing by not dusting first?”

If you would like to learn more, please visit our website:www.xkwashequip.com

leave a message

Scan To Wechat :

Hi! Click one of our members below to chat on