Request a Quote

If you operate a carpet cleaning factory, commercial laundry, hotel/mosque facility, or a professional rug care center, buying the right fully automatic industrial carpet washing machine is not just about “cleaning faster”—it directly affects cleaning quality, water consumption, labor efficiency, maintenance cost, and machine lifespan.

In this guide, you’ll learn exactly how to choose an automatic carpet & mat dust removal + washing machine, especially for markets like the Middle East and Central Asia where carpets are wider and dust is heavier.

Confirm Carpet Type + Maximum Washing Width

Start with two questions:

What materials will you wash?

Why it matters: different materials require different brush stiffness. Wool and premium rugs need soft bristles to avoid fiber damage and surface fuzzing.

What is your maximum carpet width?

The most common industrial options are:

Rule of thumb: choose a width that covers 90%+ of your daily orders—oversizing increases cost, undersizing limits your business.

Dust Removal Before Washing: Critical for Middle East & Central Asia

In many regions, carpets carry sand, dust, and outdoor debris. If you wash without pre-dusting, you often get:

• dirty water circulating faster

• reduced deep-clean performance

• higher water use and more filter cleaning

• faster brush wear

A machine with an automatic dust removal function lets you:

• remove dust as a standalone process, or

• do pre-dusting before washing for noticeably better results

XIKE solution: fully automatic dust removal + washing integrated system designed for professional carpet cleaning demands worldwide.

The Core Cleaning System: Brush Structure

Brush design is where cleaning performance is decided.

Best-practice configuration: Disc Brushes + Roller Brush

• Disc brushes: deep cleaning, underside treatment, stain agitation

• Roller brush: removes floating hair/lint and improves finishing

Hard + Soft Brush Combination (Must-have for mixed orders)

A professional machine should support:

• hard bristles for durable commercial carpets

• soft bristles for wool and high-end rugs

• zoned/sectional washing, so you can protect delicate materials while still cleaning heavy-duty carpets efficiently

XIKE configuration: 8/10/12-disc brush series with hard + soft brush system and zoned cleaning, widely preferred by commercial carpet cleaning companies.

Water Recycling + Filtration: The Real Long-Term Cost Saver

Industrial carpet washing is a volume business—your biggest hidden cost is often water + wastewater.

If water is expensive or limited, choose a machine with:

• integrated water circulation tank

• effective filtration system

• automatic spray/sprinkling design for controlled usage

XIKE advantage: integrated water recycling + automatic spraying can save 40%+ water, reducing long-term operating cost and supporting sustainability.

Motor + Drive System: Don’t Ignore Efficiency and Noise

For industrial use, prioritize:

• pure copper brushless motor (high efficiency and reliability)

• stable power output for long working hours

Avoid low-efficiency drive structures

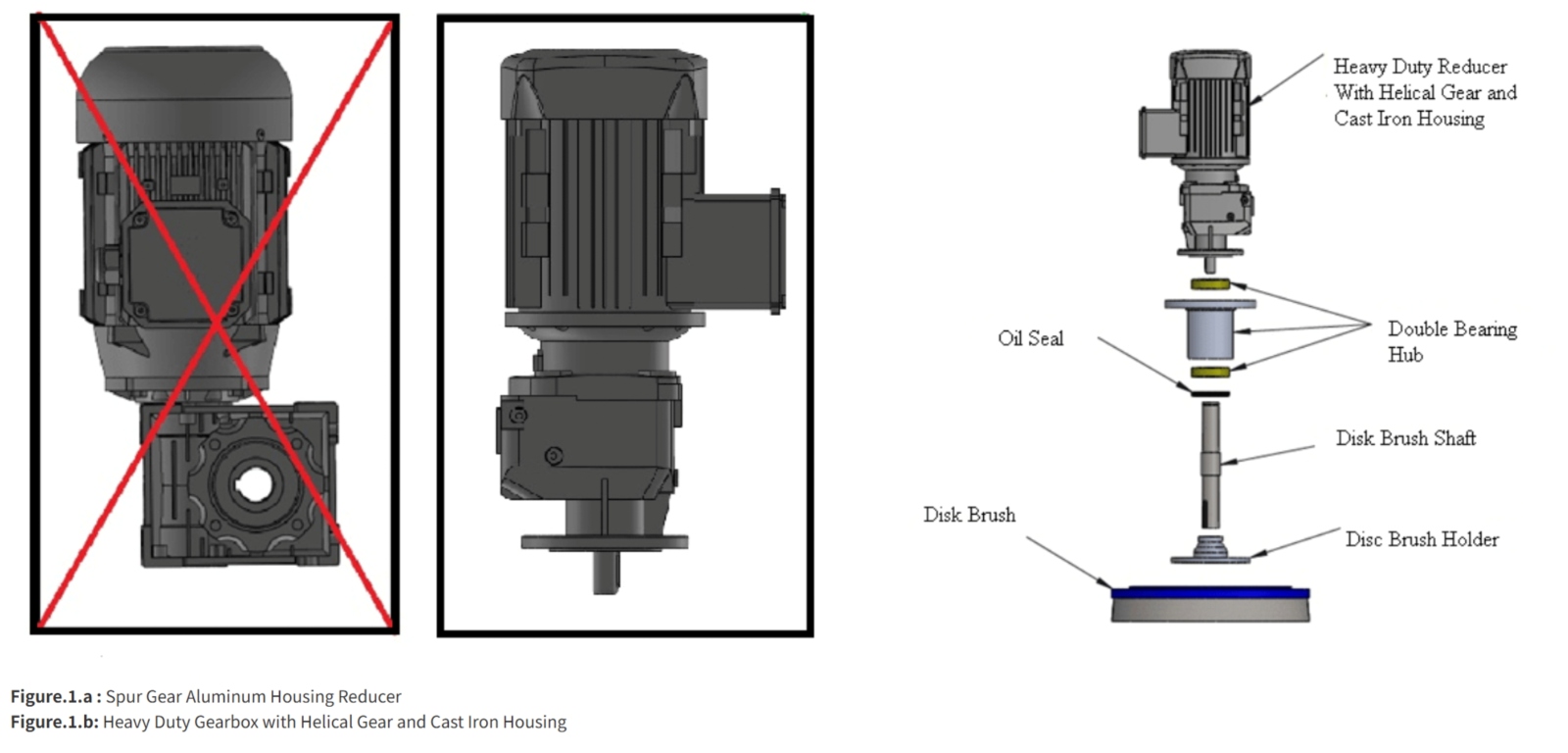

Some drive systems (e.g., spur gear designs with aluminum housing reducers) can lead to:

• higher noise

• lower efficiency

• shorter service life under heavy load

Recommended: heavy-duty gearbox with helical gear + cast iron housing for stronger torque, lower noise, and longer lifespan (used in XIKE industrial models).

Frame Thickness & Anti-Rust Materials: Industrial Machines Must Be Built Heavy

Industrial machines typically weigh 2000–5000 kg. A weak frame causes vibration, misalignment, and early failure.

Check:

• steel thickness

• galvanizing/anti-rust treatment

• structural reinforcement points

Many competitors use 3mm carbon steel. XIKE uses 5mm galvanized steel on multi-disc automatic carpet washing machines and UNIDRYER carpet spin dryers—thicker, stronger, and rust-resistant. In many cases, this makes the machine 200–500 kg heavier, improving stability and durability.

R&D Capability + Full Service Support

Carpets evolve. Customer expectations rise. Your supplier should support you beyond shipping the machine:

Look for:

• strong engineering/R&D for upgrades and customization

• pre-sales guidance (width, brushes, workflow design)

• installation & training

• after-sales service and spare parts availability

This matters most for buyers building a complete carpet washing line (dusting → washing → spin drying).

leave a message

Scan To Wechat :

Hi! Click one of our members below to chat on